MAXIMIZE YOUR SYSTEM’S FLEXIBILITY.

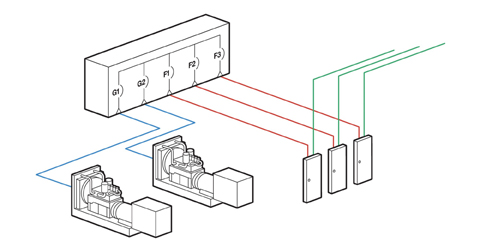

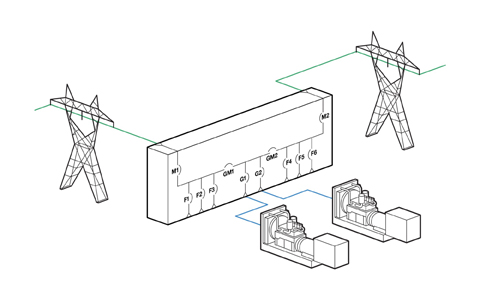

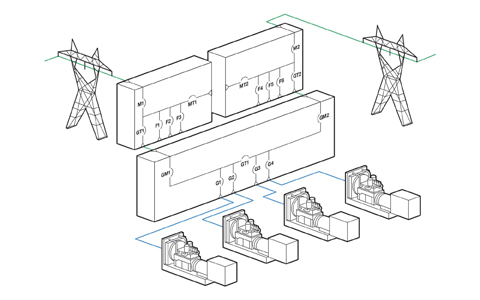

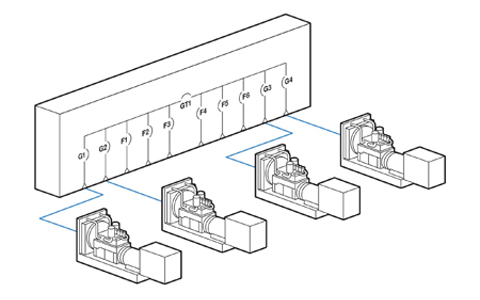

While it may be common for a facility to install a single large generator to meet its power needs, paralleling two or more generators offers a number of practical benefits and advantages over a single-generator system.

REDUNDANCY

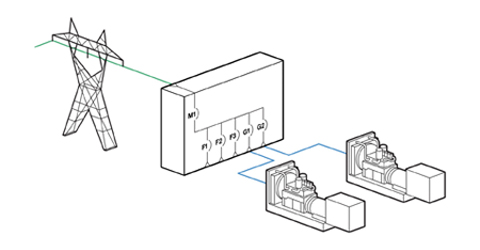

The redundancy provided by the paralleling of two or more generators delivers greater reliability and flexibility than a single generator can provide. In critical applications, having more than one generator connected to the bus at all times ensures continuous generator power in the unlikely event that a generator fails.

EFFICIENCY

Instead of one large generator that might operate at an inefficiently low kW, several small generators can be paralleled together and turned on and off as necessary to efficiently support the varying demands of the load.

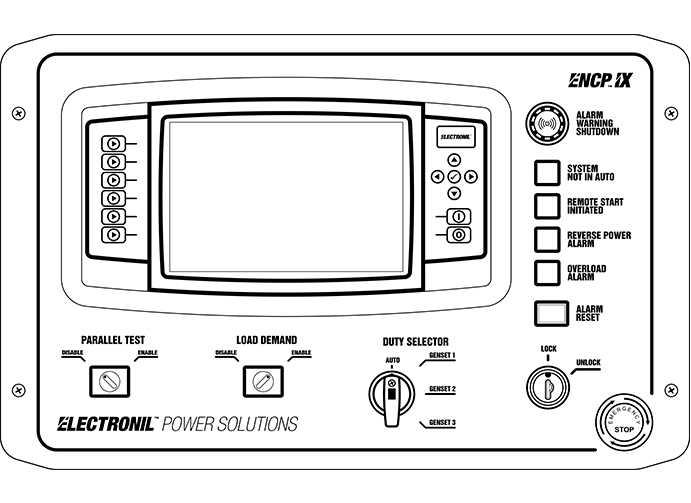

In situations where your load needs require one genset, you’ll run more efficiently. And that kind of efficiency can result in big savings. Because our ENCP 9 SERIES control systems automatically turns off any generators in your system when needs are low, you’ll benefit from immediate fuel savings and reduce running time for greater generator longevity.